Model: Double soldering iron head double station automatic soldering machine

Overall dimensions: W620mm*D600mm*H790mm

Number of motion axes: 4 axes

Operation range: X axis 300mm, Y1, Y2 axis 300mm, Z axis 100mm

Maximum speed: 600mm/sec Repeat accuracy: ±0.02mm

Drive mode: Precision stepper motor + synchronous belt + guide rail

Programming method: Handheld teaching programmer

Heating core: Wilo 150W (optional)

Temperature control range: 50-500℃

Tin wire range: sans-serif; font-size: 14px; text-wrap-style: initial; background-color: rgb(255, 255, 255);">Φ0.5-Φ1.2mm

Instructions for use of a dual-station automatic soldering machine, and an introduction to the control system operation of a desktop automatic soldering machine.mp4

The efficiency of the dual-soldering iron head dual-station automatic soldering machine is 1.8 times higher than that of the single-soldering iron model. Simple programming method, direct handle teaching, you can directly input the solder joint coordinates, you can also teach the solder joint position, and you can reproduce the solder joint position coordinates. The multi-axis manipulator and advanced motion control algorithm are used for linkage, simulating the manual tinning action, and effectively improving the positioning accuracy of the soldering iron head.

The dual-soldering iron head dual-station automatic soldering machine is suitable for mixed circuit boards, heat-sensitive components, SMT back-end processes, PCB boards, HDMI, charger plugs, connectors, DC terminals, ignition switches, sensors, USB, data cables, auto parts, security products, printed circuits, color-packaged LCD screens, computer speakers and motors, etc.

Product advantages

1. The dual-soldering iron head dual-station automatic soldering machine replaces manual specific soldering operations to realize soldering automation. Simple and convenient, high-speed and accurate, precise control of soldering.

2. Easily realize soldering of various tracks such as spot welding, drag welding, pull welding, and wire welding, and the soldering position is accurate.

3. High-performance, low-cost linear structure platform with beautiful appearance.

4. The eight-axis platform adopts advanced drive and motion control algorithms, which can effectively improve the positioning accuracy and repeatability of the end of the motion.

5. The whole machine is completely computer-controlled, and the solder joint position coordinates can be directly input digitally or taught through the handheld box.

6. Extra-high-power temperature controller with multiple functions such as adjustable temperature, temperature compensation, password management, and automatic cooling.

7. The high-precision thermocouple is located at the front end of the soldering iron, which quickly senses the slight changes in the temperature at the front end of the soldering iron to ensure the stability of the continuous soldering temperature.

8. Special automatic soldering iron tips with various styles can quickly solve difficult soldering processes.

9. The program has functions such as position correction, copying, array, and automatic positioning, and the machine operation is simple and fast.

Advantages

1. The dual-axis dual-platform rotating head automatic soldering machine has flexible and diverse soldering methods, with functions such as spot welding and drag welding (pull welding).

2. The mechanical arms of the equipment are all made of aluminum profiles, which are not deformed, rust-free, and run stably.

3. The equipment can copy the work program point-to-point and block-to-block, shortening the program writing time.

4. The equipment has an automatic cleaning function, which stabilizes the soldering quality and extends the service life of the soldering iron tip to a certain extent.

5. The multi-axis linkage manipulators are all driven by precision stepper motors and advanced motion control algorithms, which effectively improve the motion positioning accuracy and repeatability accuracy.

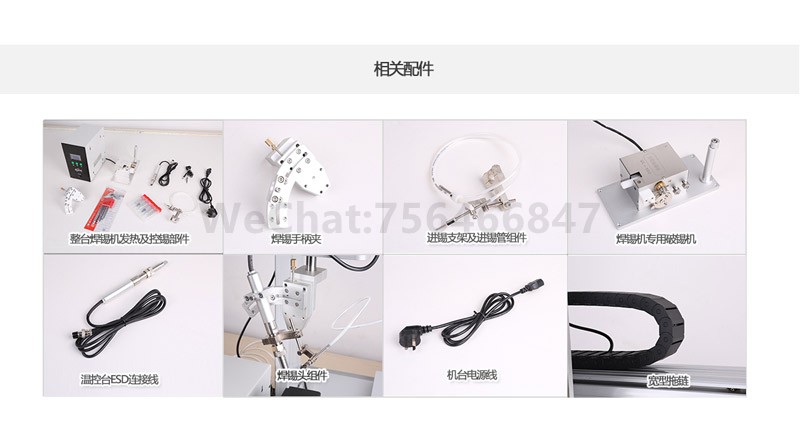

Machine configuration

◆ Four-axis welding double-station work platform

◆ One set of handheld teaching programmer

◆ Two sets of heating controllers

◆ Two sets of tin-breaking controllers

◆ Two sets of soldering pen components

◆ Two sets of soldering tips

◆ Two sets of tin-discharging components

◆ Smoke purification and filtration system (optional)

◆ Drive mode: X1/Y1Y2/Z1 four-axis micro-stepping motor

◆ Resolution capability: X/Y/Z three-axis 0.01mm:

◆ Control mode: PTP point-to-point, CP continuous path teaching control, can be repeatedly taught.

◆ Output/input: two-way, single-way 4-point input, 4-point output

◆ Mechanical size (approximately): W620mm*D600mm*H790mm

◆ Mechanical weight: 80kg

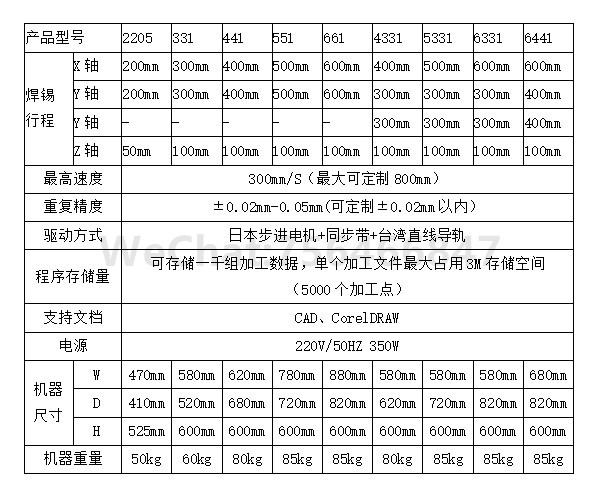

Machine parameters

COMPANY:Shenzhen Jietongtai Technology Co., Ltd

Contact:Mr. Zhou

Tel:13410974163

Phone:15338087819

Email:mail@jietongtai.com

Add:A3 Floor, Hongda Phase III Factory, No. 9-2 Xingye 3rd Road, Fenghuang Community, Fuyong Street, Bao'an District, Shenzhen