Use production lines and glue filling equipment, tunnel furnaces and other equipment to complete the complete production of automatic glue filling and encapsulation of capacitor epoxy resin. The products flowing out of the final process are complete products without manual intervention;

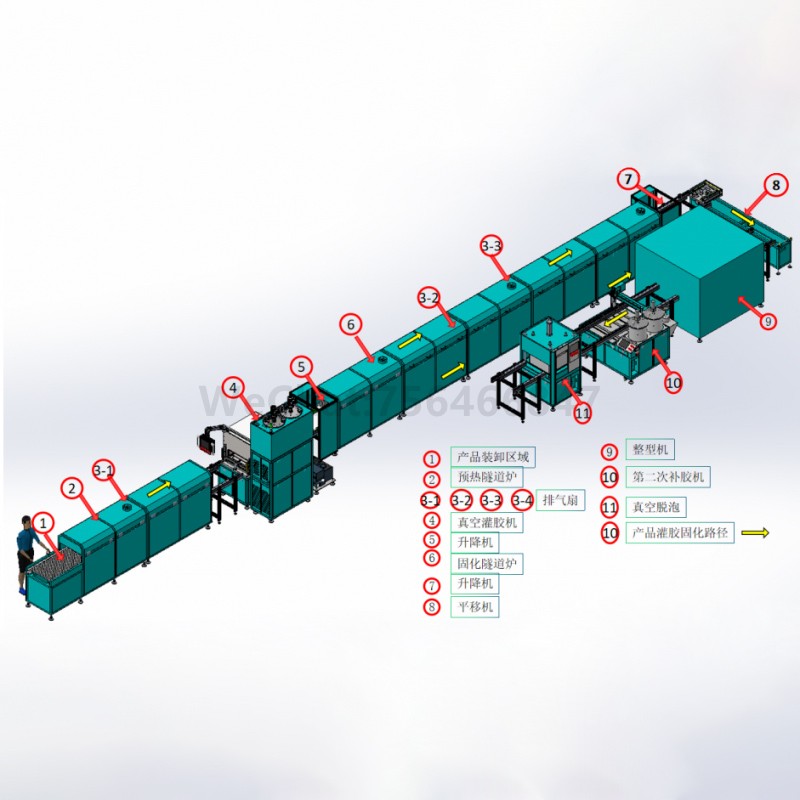

Introduction to process flow:Place the loaded product tray on the production line>>Enter the preheating short tunnel furnace>>Primary vacuum glue filling>>After glue filling, enter the long tunnel furnace for heating to quickly solidify>>After solidification, enter the shaping machine>>After coming out of the shaping machine, perform secondary glue filling (normal pressure fully automatic glue filling machine)>>After the secondary glue filling, enter the vacuum machine for degassing>After degassing, naturally solidify the glue of the secondary glue filling to complete all processes.

1. Introduction:

Purpose: Use production lines and glue filling equipment, tunnel furnaces and other equipment to complete the complete production of capacitor glue filling and encapsulation processes. The products flowing out of the final process are complete products without manual intervention;

Products: capacitors;

Glue used: epoxy resin, different types of two-component AB glue can be designed and customized;

Ratio: 5:1;

Process flow introduction: Place the loaded product tray on the production line>>Enter the preheating short tunnel furnace>>One vacuum glue filling>>After the glue filling is completed, enter the long tunnel furnace for heating to quickly solidify>>After the curing is completed, enter the shaping machine>>After the shaping machine comes out, perform secondary glue filling (normal pressure full-automatic glue filling machine)>>After the secondary glue filling, enter the vacuum machine for degassing>After the degassing is completed, naturally solidify the glue of the secondary glue filling to complete all processes.

Application range: Suitable automatic production line glue filling solutions can be provided for different products. Welcome to inquire for details.

2. Production Line Composition:

Serial number | Device Name | quantity | Remark |

1 | Tunnel baking oven | 2 units | 14 m |

1 | Glue storage system (AB glue barrel) | 2 sets | Glue filling machine |

2 | Glue supply system (plunger pump) | 2 sets | Glue filling machine |

3 | Mixing system (multi-stage mixer) | 1 set | Glue filling machine |

4 | Welding frame, exterior sheet metal | 1 set | Glue filling machine |

5 | Motion system (three-axis manipulator, motion control card) | 1 set | Glue filling machine |

6 | Cleaning system (mixed glue) | 1 set | Glue filling machine |

7 | Rubber barrel, pump, and pipeline heating system | 1 set | Glue filling machine |

8 | Vacuum system | 1 set | Glue filling machine |

9 | lifter | 2 units | Glue filling machine |

10 | 4.3 m assembly line | 1 item | Glue filling station |

11 | Translation machine | 1 units | Tunnel furnace exit |

12 | Molding Machine | 1 units | |

13 | standard glue filling machine | 1 units | |

12 | Control system (electrical cabinet, touch screen, motion control box) | 1 set | Vacuum Glue filling machine、Glue filling machine、Assembly line, elevator, translation machine, leg trimming machine, tunnel baking oven |

3. Main functions of the production line:

1. After the product enters the automatic production line, each station is automated and intelligent (if an abnormality occurs in each station or the product does not enter the next station as expected, the previous product is intercepted);

2. The entrance of each station and the connection port of the automatic line body adopt a trumpet-shaped design to ensure that the product passes smoothly without jamming;

3. The double-speed chain design of the conveyor line body reduces the friction of product transportation and positioning, and cooperates with the one-way control of the double-speed chain, and has a unique collective positioning structure. It has the characteristics of simple structure, convenient control and easy maintenance.

4. Multi-level automatic mixing;

5. Automatic cleaning function;

6. Glue barrel lack of glue alarm, full glue alarm;

7. Fully automatic glue dispensing function;

8. The glue output ratio, glue output speed, glue output time, and glue stop time only need to change the value on the touch screen;

9. Point, line, surface, arc, circle, irregular curve difference compensation and three-axis linkage functions;

10. Vacuum suction function to avoid uneven glue discharge, wire drawing, bubbles and other phenomena;

11. Dynamic stirring motor abnormal alarm;

12. Glue barrel stirring vacuum degassing glue extraction function;

13. Glue filling machine vacuum system, automatic gluing;

14. Product fixture automatic positioning and clamping (glue filling station);

15. Tunnel furnace baking line intelligent control (temperature can be set separately for each meter);

16. Alarm for full material and waiting material in the production line;

17. Continuously variable speed of production line 0-3500mm/min (customizable according to customer requirements);

18. Vacuum machine defoaming function;

19. Product trimming function;

20. Anti-solidification function (automatic timed glue removal);

21. Heating function for glue barrel, pump and pipeline (temperature adjustable);

22. Interlocking anti-fouling function for AB glue output;

23. Alarm function for glue output pipe, glue supply pump blockage and pump jam;

4. Technical parameters of automatic glue filling machine:

Glue ratio | 10:1 ---1:1 ratio adjustable |

Glue filling machine machine travel | 600*600*80mm |

Processing technology | Point, line, arc, circle, irregular curve difference compensation and three-axis linkage functions |

Displacement speed | 500mm/s |

Glue output speed | 0.3-15g/s |

Positioning accuracy | ±0.1mm |

Glue dispensing accuracy | ±1% |

Ratio accuracy | ±1% |

Program Inventory | 99个 |

Assembly line transport speed | 0-3500mm/min |

Pipeline transmission direction | L→R |

Glue filling machine heating temperature control | Room temperature ~ 80℃ (with temperature control display) |

Temperature control accuracy | ±3℃ |

Tunnel furnace heating temperature control | Room temperature ~ 150℃ (with temperature control display) |

Tunnel furnace temperature control accuracy | ±5℃ |

Storage tank stirring motor | 200RPM |

Input air pressure | 0.4MPa—0.8MPa |

Glue viscosity | 1mPa·s--100000mPa·s |

How to operate | automatic |

Proportional control | PLC/Precision plunger pump |

Flow Control | Digital Input |

Programmatically | Teaching programming |

Automation control system | Touch screen (to realize program programming, modification, storage, etc.) |

Glue control system | AB glue back-suction valve, realize independent operation of AB glue |

Hybrid | Multistage mixer |

Glue barrel system | A plastic barrel (60L) B plastic barrel (60L) |

Power | 220V/50Hz/57.73KW |

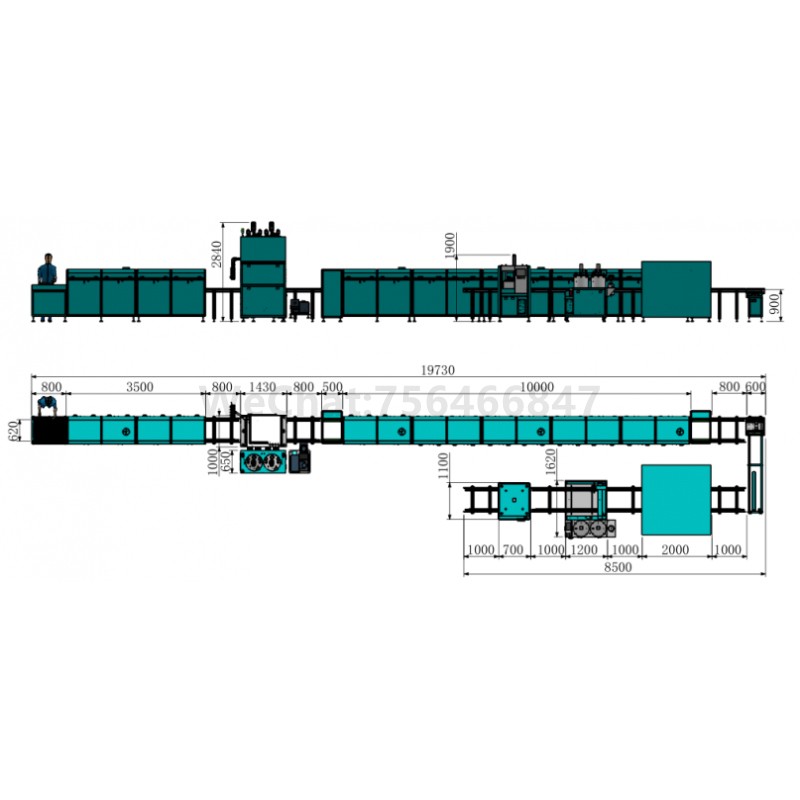

Dimensions | Glue filling machine 1500(Length)mm×1100(Width)mm×1500(Height)mm Tunnel furnace 14000(Length)mm×920(Width)mm×1440(Height)mm Vacuum glue filling machine 1500(Length)mm×2000(Width)mm×2850(Height)mm Lifting machine 800(Length)mm×600(Width)mm×1440(Height)mm Translation machine 4000(Length)mm×600(Width)mm×910(Height)mm Assembly line 4500(Length)mm×720(Width)mm×910(Height)mm |

List of single equipment used:

Epoxy resin vacuum glue filling machine, equipment that can fill epoxy resin AB glue in a vacuum environment;

Epoxy resin glue filling machine, fully automatic glue filling machine equipment used for epoxy resin (filling in a normal environment);

Other types of glue filling production lines:

Cantilever glue filling machine, placed next to the production line, with an external glue filling robot arm, can automatically fill glue for products in the production line;

Glue filling machine + curing tunnel furnace production line, a production line that heats and cures after fully automatic glue filling;

Vacuum glue filling + curing tunnel furnace production line, a production line that heats and cures after vacuum glue filling;

COMPANY:Shenzhen Jietongtai Technology Co., Ltd

Contact:Mr. Zhou

Tel:13410974163

Phone:15338087819

Email:mail@jietongtai.com

Add:A3 Floor, Hongda Phase III Factory, No. 9-2 Xingye 3rd Road, Fenghuang Community, Fuyong Street, Bao'an District, Shenzhen