Packaging & Shipping

Strong wooden cases suitable for a long distance shipment.

package weight :about 110kg

package size: about 1300(L)*580(W)*1800(H) mm

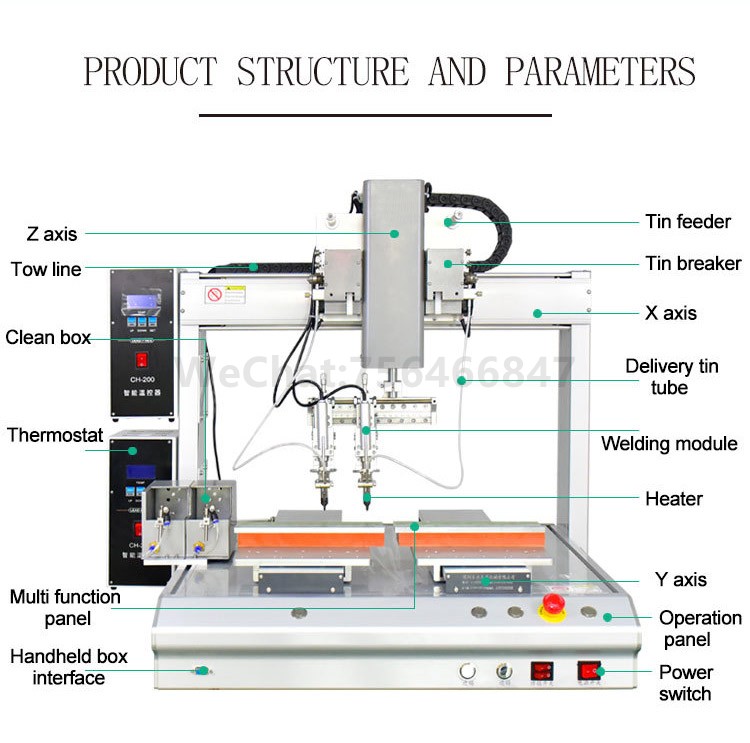

Work Area:300(x)*300(y)*100(z)mm R-axis:360°

XYZ Repeatability:±0.03mm

Instructions for use of a dual-station automatic soldering machine, and an introduction to the control system operation of a desktop automatic soldering machine.mp4

Product Model | 9W-SH431R | |||||||

Operating Range | X1-axis | 300mm | X2-axis | 300mm | X3-axis | 300mm | X4-axis | 300mm |

Y1-axis | 300mm | Y2-axis | 300mm | Y3-axis | 300mm | Y4-axis | 300mm | |

| Z1-axis | 100mm | Z2-axis | 100mm | Z3-axis | 100mm | Z4-axis | 100mm | |

R | 360° | R | 360° | R | 360° | R | 360° | |

| Dimensions

(mm) | L | 1016 | ||||||

W | 685 | |||||||

H | 800 | |||||||

Repeatability | ±0.02mm-0.05MM (Customizable within ±0.02mm) | |||||||

Control System | independent research and development | |||||||

Driving Mode | Precisely Stepping Motor+Timing belt+Taiwan brand linear guide | |||||||

Program Storage | It can store one thousand sets of processing data and a single processing file can occupy up to 3M storage space (five thousand processing points) | |||||||

File Storage Space | Handheld box 256M, offline card 32M, single processing file up to 3M storage space (100,000 processing points) | |||||||

Support Document | CAD,CorelDRAW | |||||||

Power Supply | AC220V 50 – 60HZ 350W(Selectable) | |||||||

Temperature Control Range | 0-550C° | |||||||

Control Panel | Teach pendant | |||||||

External Interface | USB + RS232 | |||||||

Soldering Method | Point Soldering/Drag Soldering | |||||||

Brief introduction

Automatic soldering machine is mainly used in electronics manufacturing, mainly for reflow soldering, wave soldering and other production equipment.

This machine is suitable for difficult process and solder processing. It is especially suitable for welding of mixed circuit boards, heat sensitive components and sensitive devices in SMT back-end process. It is widely used in PCB soldering wire, charger plug soldering and connector welding, DC terminal tinning, LED light strip connection and other fields. Automatic soldering robots replace manual welding to improve work efficiency and improve welding quality.

Features:

1, Flexible and diverse soldering methods, with spot welding, drag welding (pull welding) and other functions.

2. The mechanical arms of the equipment are all aluminum profiles, which are not deformed, rusted and stable.

3, Device writing work program can be point-to-point, block-to-block copy, shorten the programming time.

4, The device has an automatic cleaning function, to a certain extent stabilize the quality of solder processing and extend the life of the soldering iron tip.

5. Multi-axis linkage manipulators, all adopt precision stepping motor drive and advanced motion control algorithms to effectively improve motion positioning accuracy and repeatability.

6.This machine is double head and single working place,we accept the double head and double working place and so on.

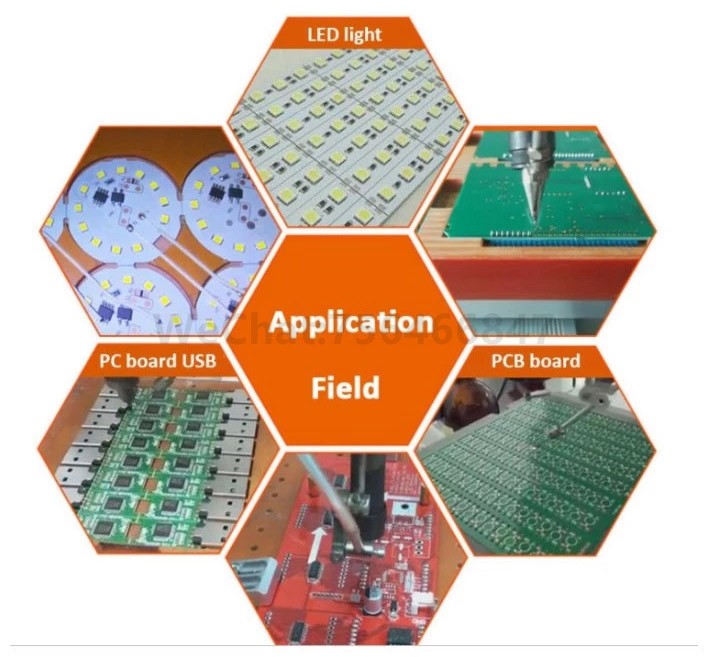

Product Application

Applications: Suitable for automotive electronics, digital, electronic, electro-acoustic, LCD, circuit board and other production industries, connectors, RJ / network transformers, cable, FPCB soldering, COF soldering, computer motherboards, CABLE, speakers and motors Wait for high quality welding.

The automatic soldering machine is mainly used in the electronics manufacturing industry. It is mainly used for process processes and solder processing that are difficult to achieve in reflow soldering and wave soldering. It is especially suitable for mixed circuit boards, heat sensitive components, and sensitive devices in the SMT back-end process. Welding, widely used in PCB welding wire, charger plug welding, connector soldering, DC terminal tinning, LED light strip connection and other fields. Automatic soldering robots replace manual welding to improve work efficiency and improve welding quality.

1 Q: Are you trading conpany or manufacturer?

A: We are manufacture.

2 Q: What is your terms of packing?

A: Generally, we pack our goods in hard brown box for small machine and plywood box for big machine.

3 Q: What is your terms of payment?

A: Payment≤10000 USD, 100% T/T in advance. Payment≥10000 USD, 50% T/T in advance, balance before shipment.

4 Q: What is your terms of delivery?

A: Sea shipping, air shipping

5 Q: How about your delivery time?

A: 7-25 days after receiving down payment. The specific time depends on the items and the quantity of your order.

6 Q: Can you produce according to the samples testing?

A: Yes, we can make testing by your sample or technical drawing.

7 Q: Do you test all your goods before delivery?

A: Yes, we test at least 5 times before shipping and running for 1 day or more.

8 Q: Warranty and after sales service

A: We provide 1 year warranty free for spare parts, Whole life technical support.

COMPANY:Shenzhen Jietongtai Technology Co., Ltd

Contact:Mr. Zhou

Tel:13410974163

Phone:15338087819

Email:mail@jietongtai.com

Add:A3 Floor, Hongda Phase III Factory, No. 9-2 Xingye 3rd Road, Fenghuang Community, Fuyong Street, Bao'an District, Shenzhen