1. Introduction to plasma surface activation and cleaning of glass cover plates

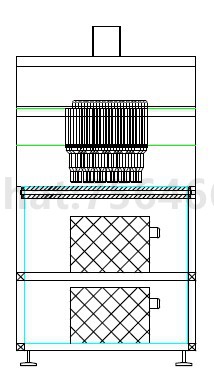

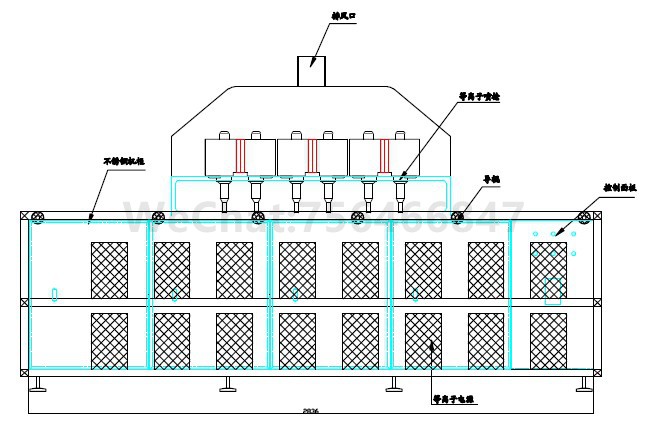

According to the requirements of the glass plate production line and the requirements for product processing, plasma surface treatment equipment can be used to process the product. The selected equipment is shown in the figure below, and the equipment appearance and plasma diagram are shown in the figure below. The energy of plasma ions and electrons can reach 6eV. Its biggest feature is that the ejected plasma is neutral and uncharged. The surface of the treated material can be modified, cleaned and etched online.

The size of each ejected plasma is: 30~90mm in diameter, and the ejection length is 25~30mm. According to the requirements of product size and processing width, flexibly select equipment for online processing.

2. Principle of plasma surface activation cleaning

Plasma is composed of a large number of free electrons and ions, and appears as an ionized gas that is approximately electrically neutral on a macroscopic scale. It is another aggregation state of matter - the plasma state, also known as the fourth state of matter. The electrons in the plasma obtain energy from the electric field and become free high-energy electrons. They collide with atoms and molecules in the gas to produce excitation and ionization. The excited molecules, atoms, ions and free radicals generated are extremely unstable and have high chemical reactivity. They are easy to react in a way that cannot be generated under normal circumstances, generate new compounds, or cause the treated material to lose weight. During treatment, the surface layer can be etched to form new properties (such as weight loss, hygroscopicity, depth enhancement, adhesion, etc.); or cause cross-linking, grafting and polymerization.

Plasma is very different from ordinary gas in nature. The electron temperature in plasma can be as high as thousands to tens of thousands of K, while the gas temperature is very low, roughly at room temperature to hundreds of degrees Celsius, and the electron energy is about a few to a dozen electron volts. This energy is greater than the bonding energy of polymer materials (several to more than ten electron volts), and can completely break the chemical bonds of organic macromolecules to form new bonds; but it is much lower than high-energy rays, only involving the surface of the material, so it does not affect the performance of the matrix.

Third, plasma technology has the following advantages in treating organic materials:

① Plasma technology is a dry process, energy-saving, pollution-free, meeting the needs of energy conservation and environmental protection;

② The treatment time is short and the efficiency is high;

③ There are no strict requirements for the materials to be treated, and it is universal;

④ Materials with more complex shapes can be treated, and the uniformity of the surface treatment of the materials is good;

⑤ The treatment temperature is low;

⑥ The effect on the surface of the material only involves a few to a few hundred nanometers, which will only improve the surface properties of the material without affecting the properties of the matrix.

COMPANY:Shenzhen Jietongtai Technology Co., Ltd

Contact:Mr. Zhou

Tel:13410974163

Phone:15338087819

Email:mail@jietongtai.com

Add:A3 Floor, Hongda Phase III Factory, No. 9-2 Xingye 3rd Road, Fenghuang Community, Fuyong Street, Bao'an District, Shenzhen