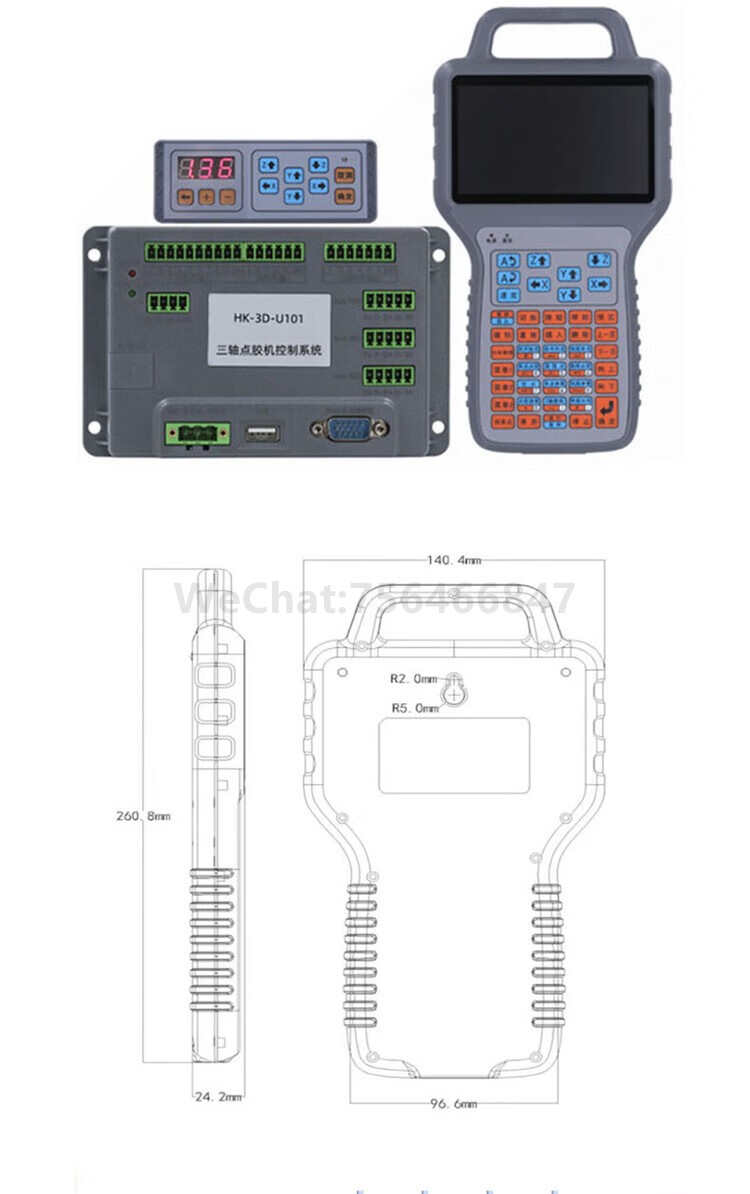

Fully automatic dispensing machine control system CAD drawing handle programming

The Hengkong three-axis dispensing motion control system has 3 motor control axes, which can support gantry-type three-axis automatic dispensing motion control, and basically meets the needs of the existing gantry-type automatic dispensing control method. The handheld programmer used adopts a 480 * 272 pixel 16 million color true color 5-inch LCD screen to make the programming menu content richer. The mainboard and the handheld programmer use industrial field bus communication connection, which has higher speed and stronger anti-interference. The handheld programmer can store dispensing processing files and system configuration files. When multiple devices are used, the handheld programmer can be used to copy dispensing processing files or system configuration files to each other (it can also be copied using a U disk). It adopts the ARM+DSP control solution, has powerful computing power, very small speed refresh time, excellent motion control acceleration and deceleration performance, and can support high-precision and high-speed three-dimensional linear and three-dimensional space arc motion. The motion control mainboard has 32M storage space, which can store 150 dispensing processing files. Each file can store 1900 dispensing processing programming points. It can support working without a handheld programmer. The dispensing processing files can be selected by digital tube plus key. Box Hengkong motion control card set

Features

1. Rich motion instructions and auxiliary instruction sets Convenient and friendly file teaching and editing functions, and provide batch modification, array copying, graphic translation, graphic scaling, automatic rounding and other advanced editing functions;

2. Corner processing can set the priority of speed and path fit to achieve smooth transition of corners;

3. DXF file conversion function, which can export DXF files of CAD dispensing path diagrams into dispensing files;

4. There are 10 "undo" and "redo" functions for editing programming points to effectively prevent misoperation;

5. Dispensing parameter settings are set in the form of programming points, which can achieve different dispensing parameter settings in different areas during the same dispensing process;

6. When returning to the origin, the X, Y, and Z axes simultaneously perform origin capture after each axis returns to the origin;

7. Support hidden menu function;

8. Support trajectory lag opening function and early closing function to solve the problem of glue accumulation at the starting point and end point.

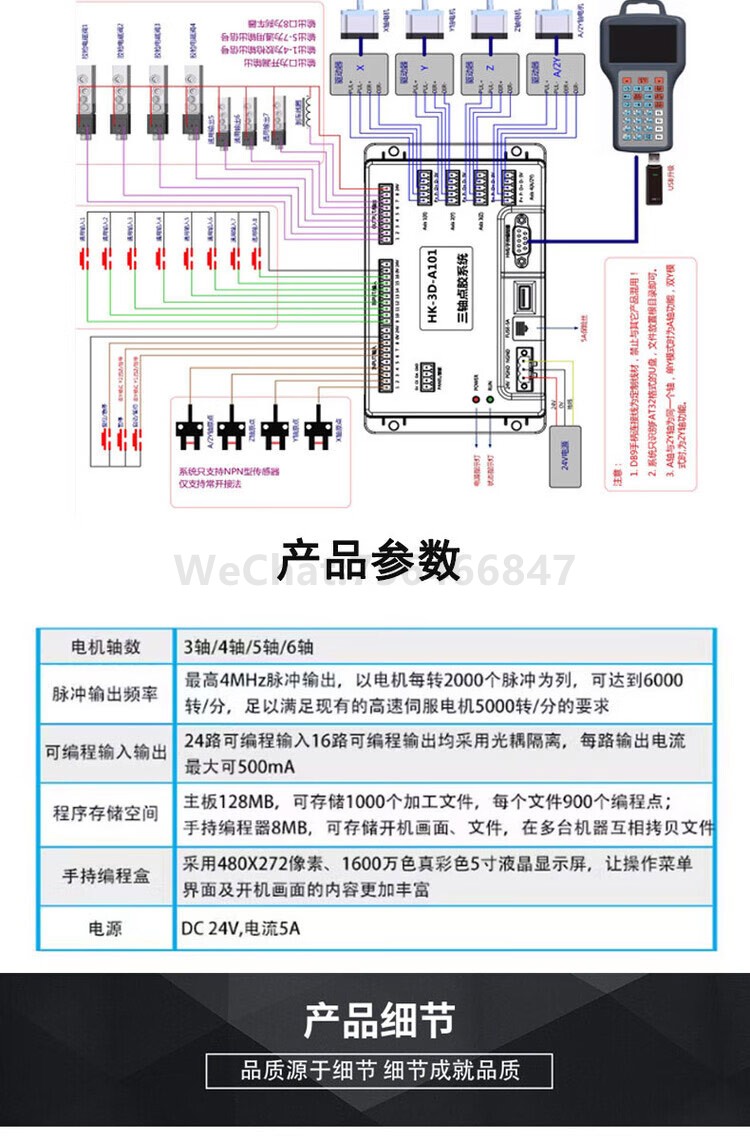

Technical parameters

| Motor shaft number | 3-axis, supports 3D linear and 3D circular hardware interpolation motion |

| Pulse output frequency | Maximum frequency 4MHz, acceleration and deceleration speed refresh time 0.1mS |

| Programmable input and output | 12 universal inputs, 6 universal outputs |

| Dedicated input and output | XYZ axis origin multiplexing signal input, 12-way function key multiplexing input, one-way dispensing signal multiplexing output, one-way brake control signal multiplexing output |

| Program storage space | 150 groups of processing files, each group stores 1900 programming points |

| External Interface | A USB port |

| Handheld programmer | 5-inch true color LCD screen, resolution 480*272 |

| Dimensions | 150mm*94mm |

| power supply | DC24V/2A |

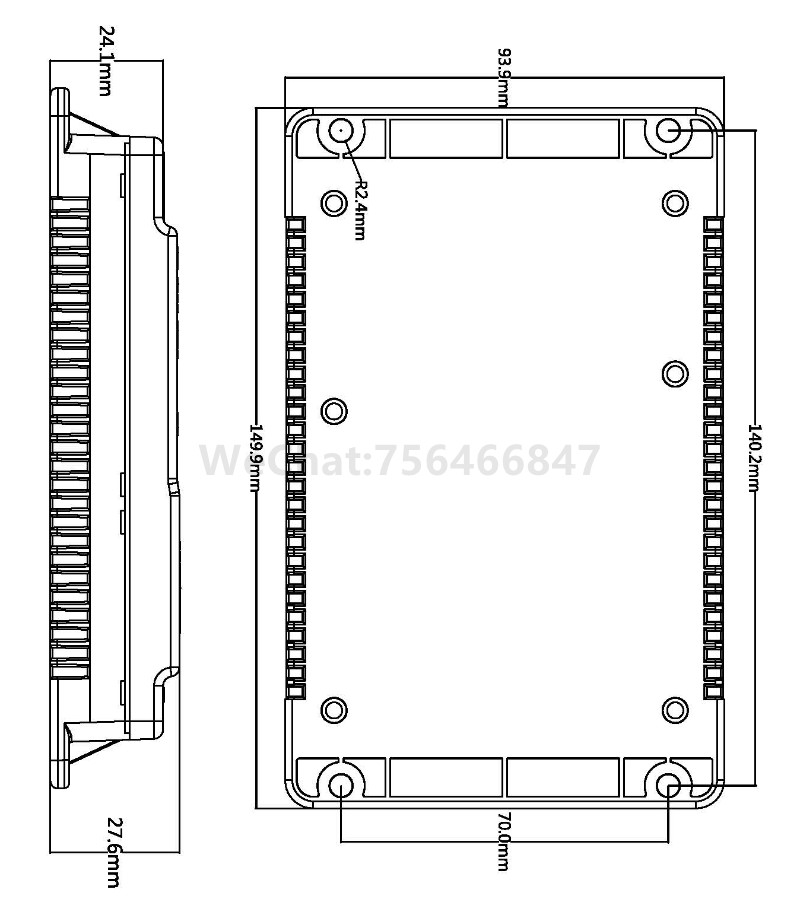

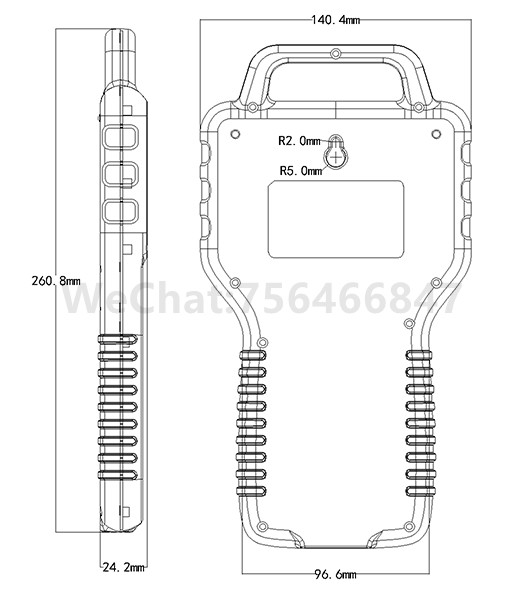

Installation dimensions

Mainboard dimensions:

Handheld dimensions:

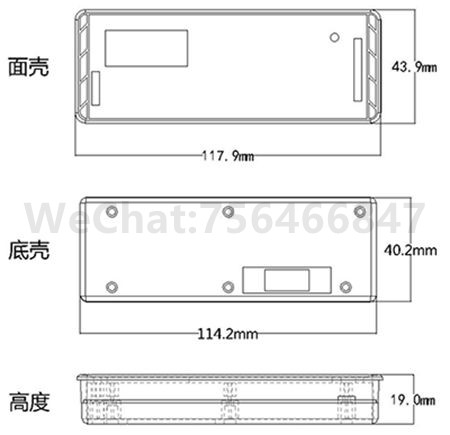

Digital tube size diagram:

COMPANY:Shenzhen Jietongtai Technology Co., Ltd

Contact:Mr. Zhou

Tel:13410974163

Phone:15338087819

Email:mail@jietongtai.com

Add:A3 Floor, Hongda Phase III Factory, No. 9-2 Xingye 3rd Road, Fenghuang Community, Fuyong Street, Bao'an District, Shenzhen