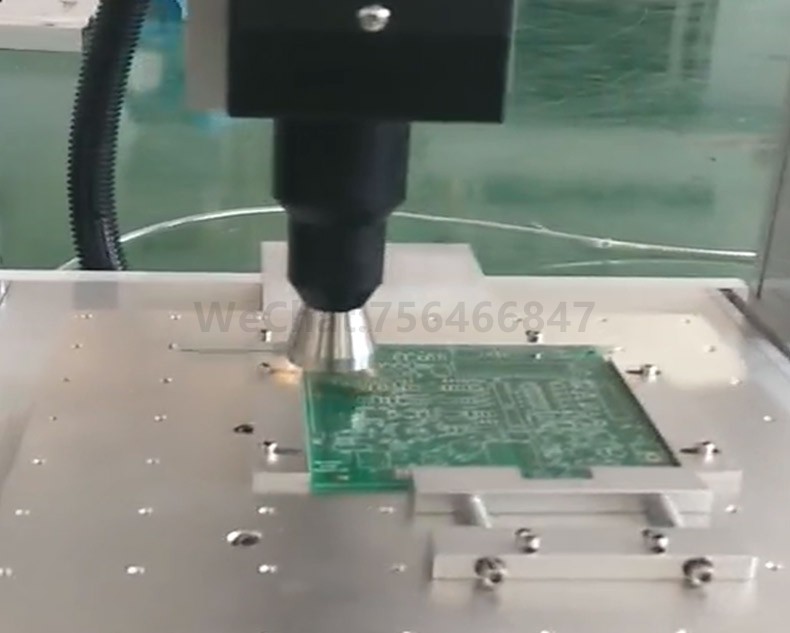

*The plasma flow ejected by the direct-injection plasma surface treatment machine is neutral and non-charged, and can be used for surface treatment of various polymers, metals, glass, rubber, PCB circuit boards and other materials;

*Improve the bonding strength of plastic parts. For example, PP materials can be improved several times after treatment. The surface energy of most plastic parts can reach more than 60 dynes after treatment;

*The surface performance after plasma treatment is long-lasting and stable, and the retention time is long;

*The dry method is pollution-free and wastewater-free, which meets environmental protection requirements;

*It can be processed online on the production line to reduce costs;

*After being treated by the plasma surface processor, ordinary glue can be used to glue the box, which reduces production costs.

*Plasma surface treatment and glue dispensing are integrated. Glue is dispensed immediately after surface treatment. It does not occupy workstations and saves personnel.

Features of automatic plasma treatment glue spraying machine:

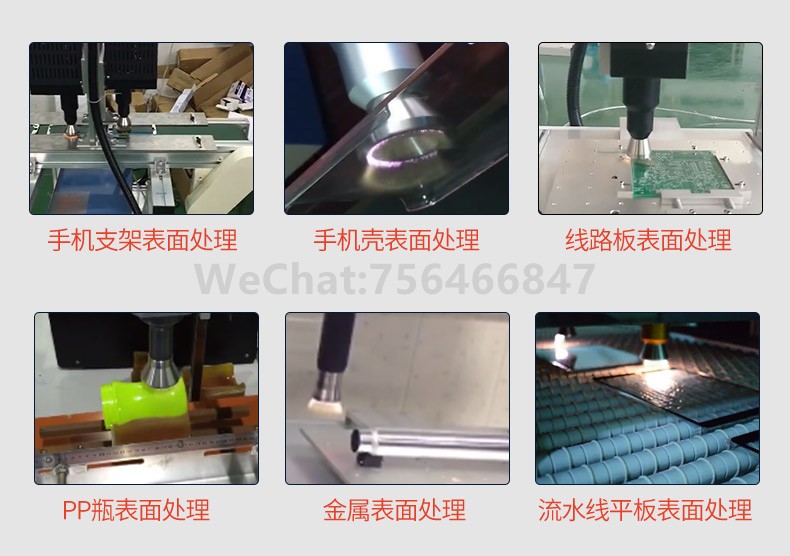

*The plasma flow ejected by the direct-injection plasma surface treatment machine is neutral and non-charged, and can be used for surface treatment of various polymers, metals, glass, rubber, PCB circuit boards and other materials;

*Improve the bonding strength of plastic parts. For example, PP materials can be improved several times after treatment, and most plastic parts can reach a surface energy of more than 60 dynes after treatment;

*The surface performance after plasma treatment is long-lasting and stable, and the maintenance time is long;

*Dry method treatment is pollution-free and wastewater-free, meeting environmental protection requirements;

*It can be processed online on the production line to reduce costs;

*After being treated by the plasma surface processor, ordinary glue can be used to glue the box, reducing production costs.

*Plasma surface treatment and glue dispensing are integrated. Glue dispensing immediately after surface treatment. It does not take up workstations and saves manpower.

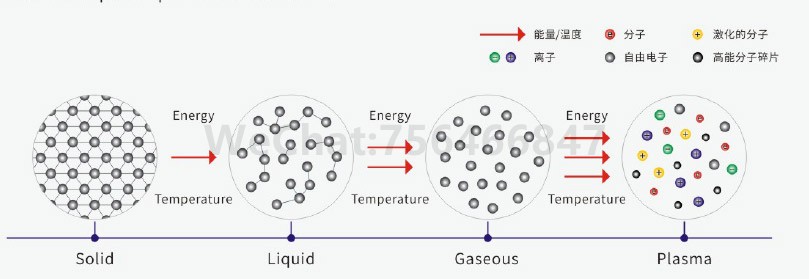

Plasma is the fourth state of matter, different from solid, liquid and gas; it is composed of a collection of ions, electrons and non-ionized neutral particles, and is a neutral state of matter as a whole.

There are a large number of active particles in low-temperature plasma, which can excite, ionize or break bonds of reactant molecules. It will not cause pyrolysis or ablation of the treated materials, so it has unique application value in modifying the surface of polymer materials. Plasma surface treatment has significant advantages such as low cost, no waste and no pollution, and can achieve treatment effects that are difficult to achieve with traditional chemical methods. Currently, low-temperature plasma surface treatment is widely used in many fields such as metals, microelectronics, polymers, biofunctional materials, low-temperature sterilization and pollution control.

High temperature plasma

When the electron temperature and ion temperature in plasma are equal, it is an equilibrium plasma, and the system temperature can reach tens of thousands of degrees, also known as high-temperature plasma. The stars in the universe continuously emit high-temperature plasma.

Low temperature plasma

When the electron temperature in a plasma is much higher than the ion temperature, it is a non-equilibrium plasma. The electron temperature can reach tens of thousands of degrees, while the temperature of ions and neutral particles can be as low as room temperature. Therefore, the temperature of the entire system is very low, which is called low-temperature plasma. Plasmas generated by general gas discharge are all low-temperature plasmas.

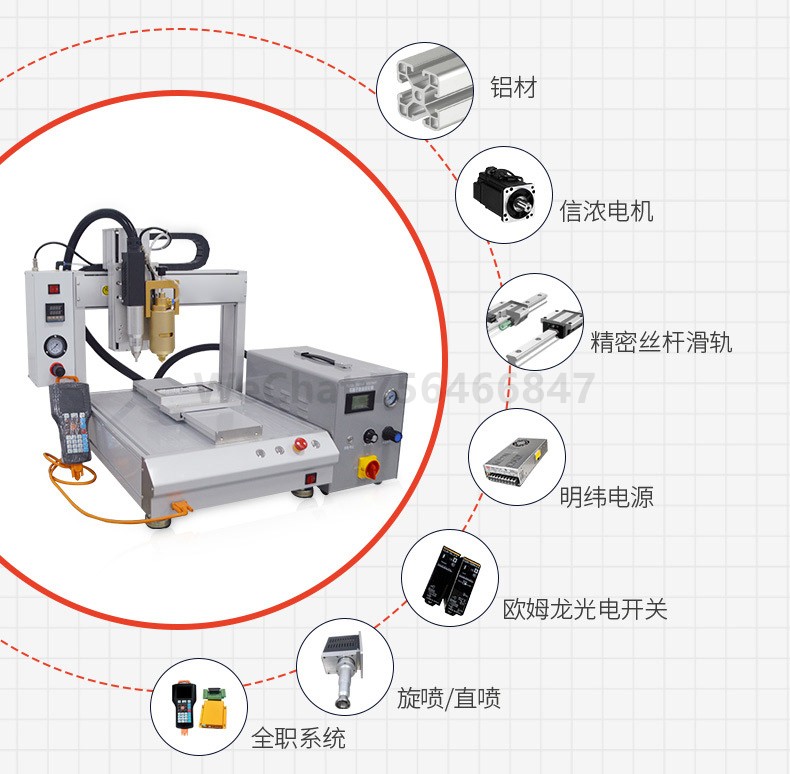

Stable performance and low failure rate

All use original high-end accessories to achieve high precision, excellent quality, stable and durable

Surface treatment dispensing machine

One machine for two purposes, cost saving, efficient work and labor saving

Glue is dispensed immediately after the product surface is treated, saving the time of taking the product to another machine for glue dispensing. It is convenient, fast, time-saving, labor-saving and improves efficiency

It can always give you surprises at critical moments

It is a plasma processor and also a glue dispenser

Flexible and multi-purpose, cost-saving, intelligent and efficient, can be used as a plasma processor or a glue dispenser alone

High efficiency processing, environmental protection and no pollution

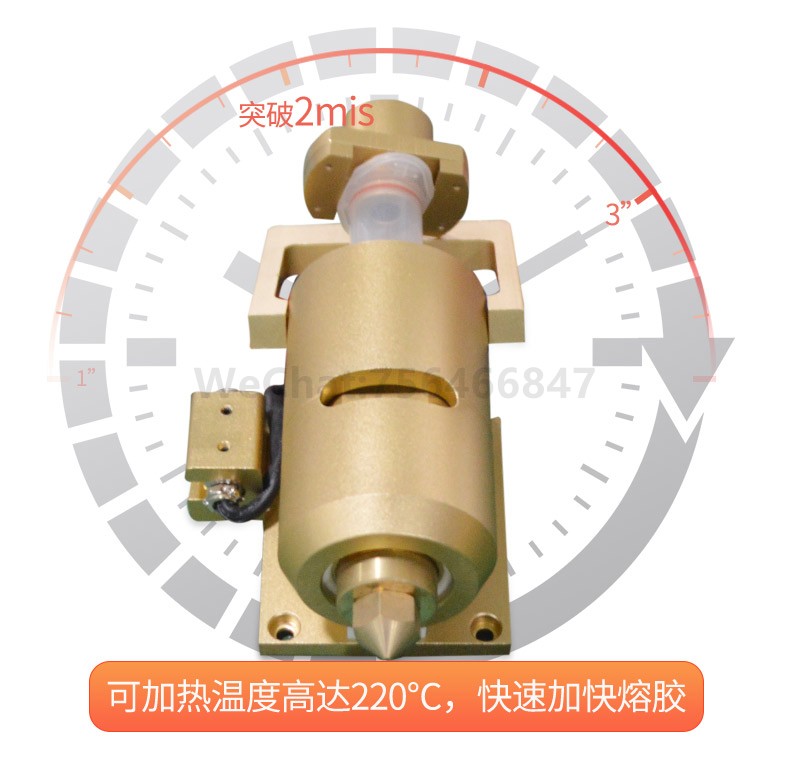

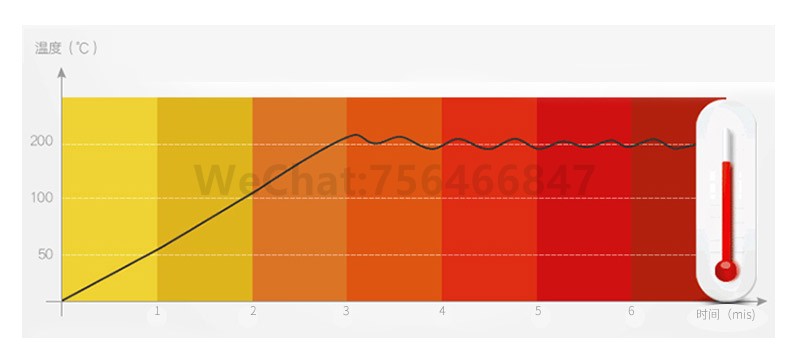

Quick processing to achieve the desired effect in about 2 seconds

Low temperature plasma does not damage the product, no need to add any chemical agents, no pollution during the treatment process, green and environmentally friendly, adjustable temperature, adjustable speed, improves hydrophilicity, adhesion, and surface bonding durability

30ML Heating Dispensing Head

30ML capacity, quick and easy glue change, independently developed and produced hot melt glue dispensing heating head, fast constant temperature insulation and durable, no drawing, no glue overflow, glue break, precise glue dispensing

Mature cases, one-stop solution

The applicable fields are quite wide, mainly including automobile manufacturing, mobile phone manufacturing, textile printing and dyeing, medical equipment, advanced coating, home appliance manufacturing, semiconductor packaging, FPC/PCB manufacturing, new energy field, flat panel display, LCD assembly, thin film process

COMPANY:Shenzhen Jietongtai Technology Co., Ltd

Contact:Mr. Zhou

Tel:13410974163

Phone:15338087819

Email:mail@jietongtai.com

Add:A3 Floor, Hongda Phase III Factory, No. 9-2 Xingye 3rd Road, Fenghuang Community, Fuyong Street, Bao'an District, Shenzhen