This solution is a glue filling line solution designed for a temperature controller (temperature sensor). It uses automatic glue filling with two-component AB glue and is cured by heating in a tunnel furnace. At present, our company can provide complete assembly line solutions for a variety of different products;

As a non-standard solution, the glue filling machine production line has different requirements for assembly line glue filling for each manufacturer. We have listed a certain customer, their product requirements, situations, and solutions in detail. This page is intended to introduce the glue filling solution for the production line for website visitors to understand. However, if you need more specific solution details or need glue filling solution planning for other product production lines, please contact our company;

Application scope of glue filling machine production line:

General electronic products are widely used, such as: capacitors, power modules, sensors, mutual inductors, transformers, IGBTs, lithium batteries, LEDs, rectifier bridges, inductors, lightning protection modules, water meters, motors, high-voltage packages, etc. Other industries such as the building materials industry also occasionally use it. At present, it has accumulated rich cases in multiple product fields.

Situation introduction:

The manufacturer's products are temperature sensors, with a monthly output of one million products and an average daily output of about 40,000 products. Seeking to achieve a fully automatic assembly line glue filling and encapsulation solution.

Manufacturer's requirements:

1. Realize glue filling in a fully automated production line, and the production line can be debugged online.

2. Reduce glue bubbles during glue filling.

3. Epoxy resin glue can be heated and cured, and a baking furnace must be configured in the assembly line (after curing, it can quickly enter the next process);

Fully automatic temperature sensor glue filling machine production line solution introduction:

1. According to "demand", our company proposes the following solutions:

1. One production line, equipped with two fully automatic glue filling machines (one glue filling, two glue filling);

2. An alcohol automatic spraying device (here alcohol spraying is used to solve the problem of glue bubbles, and glue filling machine plus vacuum machine vacuum degassing production line and other solutions can also be used);

3. A five-meter product heating furnace (complete heating and curing);

The product automatically enters the glue filling production line for two glue filling operations. After the glue filling is completed, it is cured through a tunnel furnace. After curing, the product is removed from the fixture to the next process, and the fixture continues to be recycled.

2. Additional configuration description:

1. Use alcohol spray: spraying alcohol on the surface of the product can increase the surface tension of the glue, burst the glue bubbles, and then discharge the air by itself;

2. Use two fully automatic glue filling machines to perform two glue filling operations, and then spray alcohol; the first glue filling is to fill about 70% of the glue,

the glue will penetrate into the gap of the product (for glue with less fluidity), and then perform a second glue filling (glue filling) to achieve the purpose of reducing bubbles;

Production rhythm and renderings:

1. Solution concept steps:

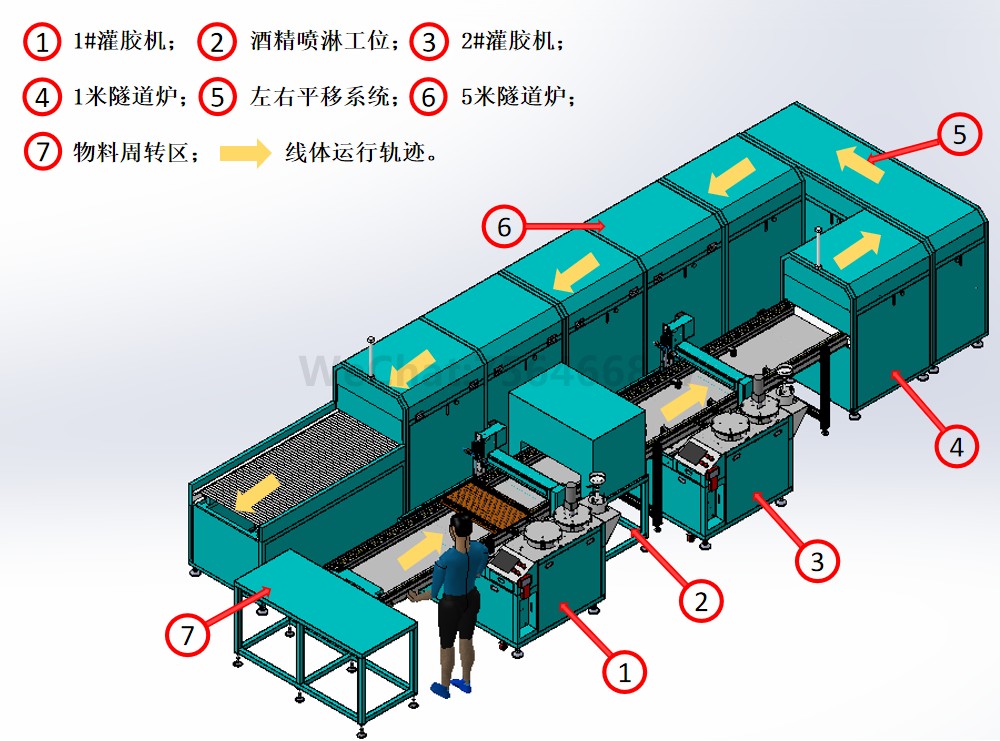

Product placement on the fixture >>> flow into the first glue filling station >>> alcohol spray >>> second glue filling >>> enter the tunnel furnace for baking and curing >>> remove the product (complete the glue filling process)

2. Production rhythm:

The initial line speed is set to 0.25 meters/minute. The production line flows out a tray of cured products every 110 seconds. About 30 trays of products can be produced per hour. Each tray of the fixture can hold 80 products, and the output per hour is about 2,000 or more.

Fully automatic temperature sensor glue filling production line renderings

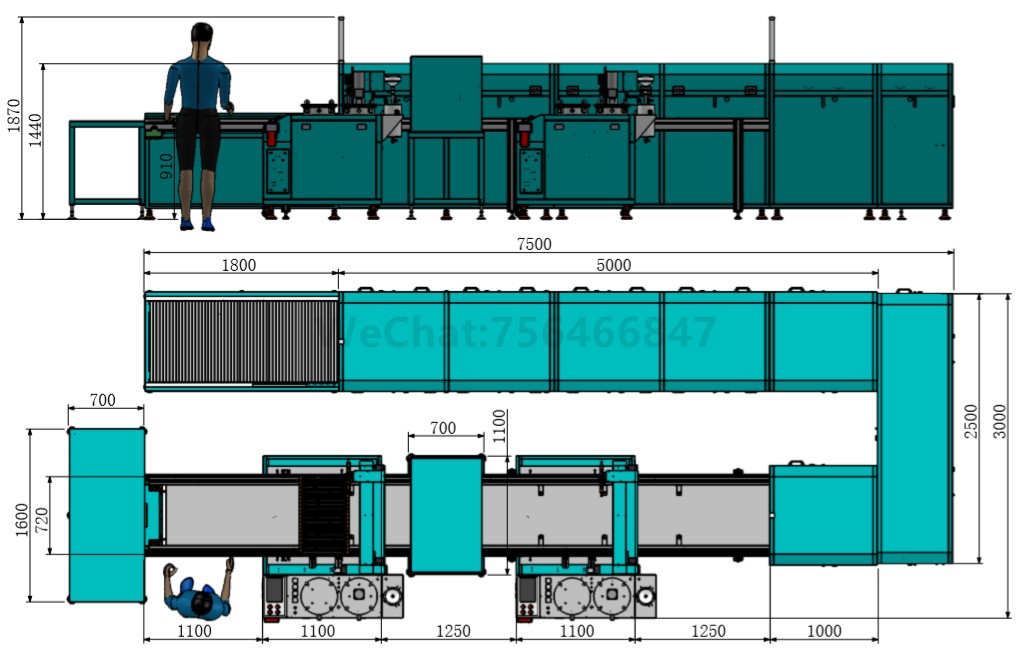

Glue filling machine assembly line dimensions (unit: cm):

Detailed dimensions of the assembly line glue filling machine

Glue filling machine production line composition:

Serial Number | Equipment name | Quantity | Notes |

1 | Tunnel oven oven | 2 Set | 1m/5m |

2 | Gum storage system (AB glue bucket) | 4set | Potting machine |

3 | Glue supply system (plunger pump) | 4set | Potting machine |

4 | Mixing system (multi-stage mixer) | 2 set | Potting machine |

5 | Welding rack, appearance metal plate | 2 set | Potting machine |

6 | Motion system (three-axis manipulator, motion control card) | 2 set | Potting machine |

7 | Cleaning system (mixed glue) | 2 set | Potting machine |

8 | Rubber bucket, pump and pipeline heating system | 2 set | Potting machine |

9 | Vacuum pumping system | 2 set | Potting machine |

10 | Translation machine | 1 Set | Potting machine |

11 | Alcohol spray mechanism | 1 Set | One program interface is reserved for secondary glue injection |

12 | 5.8 M assembly line | 1 Set | Glue filling station |

13 | Fixture positioning mechanism | 2 set | Glue filling station |

14 | Control system (electrical cabinet, touch screen, motion control box) | 1 set | Potting machine, assembly line, translation machine, alcohol spray mechanism, tunnel oven |

Main functions of glue filling machine equipment:

1. After the product enters the automatic production line, each station is automated and intelligent (if an abnormality occurs in each station or the product does not enter the next station as expected, the previous product is intercepted);

2. The entrance of each station and the connection port of the automatic line body adopt a trumpet-shaped design to ensure that the product passes smoothly without jamming;

3. The double-speed chain design of the conveyor line body reduces the friction of product transportation and positioning, and cooperates with the one-way control of the double-speed chain, and has a unique collective positioning structure. It has the characteristics of simple structure, convenient control and easy maintenance.

4. Multi-stage automatic mixing;

5. Automatic cleaning of glue at the mixing tube;

6. AB glue barrel lack of glue alarm, full glue alarm;

7. Fully automatic glue dispensing function

8. The glue output ratio, glue output speed, glue output time, and glue stop time can be changed by simply touching the touch screen;

9. Point, line, surface, arc, circle, irregular curve difference compensation and three-axis linkage functions;

10. Vacuum suction function to avoid uneven glue discharge, wire drawing, bubbles and other phenomena;

11. Dynamic stirring motor abnormal alarm;

12. A glue barrel stirring;

13. Glue filling machine vacuum system, automatic gluing;

14. Epoxy resin A glue barrel heating, pump, pipeline heating (adjustable from room temperature to 80℃);

15. Automatic positioning and clamping of product fixtures (glue filling station);

16. Intelligent control of tunnel furnace baking line (temperature can be set separately for each meter);

17. Alarm for full material and waiting material of production line;

18. Continuously variable speed of production line 0-3500mm/min (can be customized according to customer requirements).

Other types of glue filling production lines:

1. Cantilever automatic glue filling machine. Directly fill glue on the assembly line, which can be used in conjunction with assembly line production;

Glue filling products: electromagnetic clutch, mechanical glue filling arm extending outward, can track the filling and sealing of products on the assembly line body;

2. Fully automatic glue filling machine + vacuum degassing production line solution. Automatic glue filling machine is used on the production line. After automatic glue filling, the product is vacuumed and degassed;

3. Vacuum glue filling machine + tunnel furnace curing production line + fully automatic glue filling machine + vacuum degassing machine. After the fully automatic vacuum glue filling machine, heat and cure to complete the first glue filling process. The fully automatic glue filling machine is used for the second time to fill glue and fill glue, and then vacuum degassing is performed;

COMPANY:Shenzhen Jietongtai Technology Co., Ltd

Contact:Mr. Zhou

Tel:13410974163

Phone:15338087819

Email:mail@jietongtai.com

Add:A3 Floor, Hongda Phase III Factory, No. 9-2 Xingye 3rd Road, Fenghuang Community, Fuyong Street, Bao'an District, Shenzhen