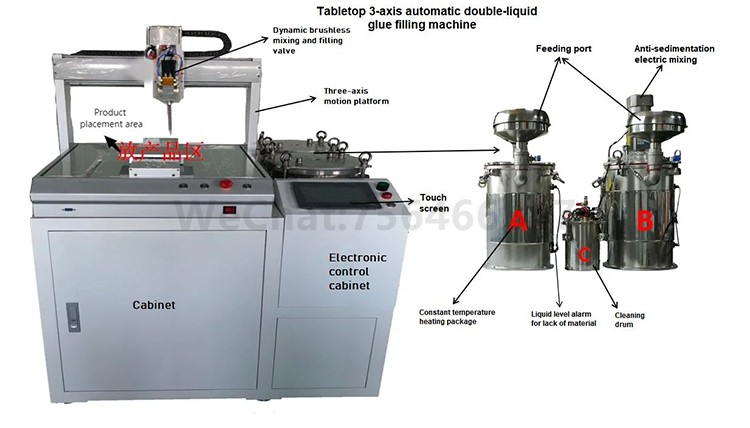

two-component AB glue mixer machine pouring compound ratio 10:1/1:1/100:12 automatic glue filling machine

Packaging & Delivery

Selling Units:Single item

Single package size: 143X65X129cm

Single gross weight:252kg

Package Type:wooden box

Lead Time :

Quantity(Sets):1 - 1 >1

Est. Time(days):15 To be negotiated

1 | Model | MS-GJJ330 |

2 | Mixing ratio | 1:1--10:1 adjustable |

3 | Dispensing Speed | According to customer's product requirements and glue types |

4 | Motion trail | Dot , line ,curve ,circle |

5 | Operation Range (X*Y*Z) (mm) | 300*300*100mm |

6 | Axis | 3 Axis (X,Y,Z) |

7 | Maximum Speed | X,Y 500mm/S, Z 300mm/S |

8 | Accuracy | ±2%(output volume)±2%(mixing) |

9 | Teaching Method | Manual Data Input/Optional: LCD Touch Screen |

10 | Motor system | precision stepper motor |

11 | Transmission mode | Precision Stepping Motor+Timing belt |

12 | Control Panel | Teach pendant (optional:PC or Touch Screen) |

13 | Power supply | AC220V 50HZ 2KW |

14 | Out-glue control system | AB glue back suction valve, achieve AB glue independent operation |

15 | Mixing method | dynamic mixing |

16 | Viscosity range | 50-20000cps |

17 | Power Source | Electricity + Pneumatic |

18 | Air pressure requirement | 0.4 to 0.8MPa (4 to 8kg/cm2) as dry air |

19 | Size | 1300(L) *900(W)*1650(H)mm |

20 | Weight(kg) | About 200kg |

21 | Feed system | manual/semi-automatic(vacuum suction) |

22 | Work condition | Humidity:20-90%, Temperature :0-40°C |

Parameters:

Application Cases:

Advantages:

1. Simple operation, stable operation and strong applicability.

2. Double barrel design, with separate storage of A and B glue.

3. Ensures that the glue will not solidify after being stored for a long time.

4. Accurate ratio, quantitatively out glue.

Application:

It suits for mixing and potting various types of two components materials, that requires to use manually or potable mixing head. Able to apply material on electric (wire) road board industry, electronic components industry, electric light source industry, small home appliance industry, igniter industry, automotive supplies industry, vacuum cleaner industry, filter industry and many other fields.

Suitable Material: For waterproof, adhesive, fixed two-component adhesive.

Such as: Crystal or less additive glue --Silicone, epoxy, polyurethane(PU), etc.

Product description:

The two-component Mixing and Dispensing System accurately meters, mixes and dispenses two-component materials like potting compounds, encapsulants, casting materials and adhesives. The two components are precisely metered using gear pump technology, programmable from a simple control panel. The mix ratio, dispensing rate and dispensed quantity can be set-up quite accurately, providing consistent, error-free metering, mixing and dispensing. The control panel is menu-driven and password protected.

Our machine is designed with a unique modular approach, for simple configuration and maintenance. Each machine is built to match your material and process, with appropriate material reservoir sizes and dispensing hose lengths. Reservoir options include agitation, heating and drying (the latter for moisture sensitive materials like polyurethanes).

Material is fed from the two integrated gravity-fed reservoirs through the gear pumps where it is accurately metered, through flexible hoses to a dispensing head. Industry standard static mixing nozzles/ dynamic mixing are used for homogeneous mixing. The mixture is free of air bubbles.

This metering, mixing and dispensing system is configured for standalone operation, triggered by a fingertip switch or foot pedal. It can also be configured to work with automation for consistently dispensed amounts and accurate placement.

The Metering, Mixing and Dispensing System is able to process a number of materials including silicones, polyurethanes and epoxies.

1 Q: Are you trading conpany or manufacturer?

A: We are manufacture.

2 Q: What is your terms of packing?

A: Generally, we pack our goods in hard brown box for small machine and plywood box for big machine.

3 Q: What is your terms of payment?

A: Payment≤10000 USD, 100% T/T in advance. Payment≥10000 USD, 50% T/T in advance, balance before shipment.

4 Q: What is your terms of delivery?

A: Sea shipping, air shipping

5 Q: How about your delivery time?

A: 7-25 days after receiving down payment. The specific time depends on the items and the quantity of your order.

6 Q: Can you produce according to the samples testing?

A: Yes, we can make testing by your sample or technical drawing.

7 Q: Do you test all your goods before delivery?

A: Yes, we test at least 5 times before shipping and running for 1 day or more.

8 Q: Warranty and after sales service

A: We provide 1 year warranty free for spare parts, Whole life technical support.

COMPANY:Shenzhen Jietongtai Technology Co., Ltd

Contact:Mr. Zhou

Tel:13410974163

Phone:15338087819

Email:mail@jietongtai.com

Add:A3 Floor, Hongda Phase III Factory, No. 9-2 Xingye 3rd Road, Fenghuang Community, Fuyong Street, Bao'an District, Shenzhen