Product name:drop glue machine

Dispensing Volume:

10-100g/5s(based on 1:1 glue proportion)

Dispensing Precision: Glue Amount±1%, Glue Proportion±1%

Input Pressure Range:0.5-0.8MPa

Head Seal Pressure: MAX≤2.6Mpa

Adhesive Viscosity:<10000CPS

Operating Model: Automatic/Manual

Programming:Handheld Programmer

Control: PLC+LCD

Mixing System: High-speed Dynamic Mixing Device

Specification:

| Floor type 2 components glue dispensing machine | |||||||

| Model | PJ180 | SZ700 | SZ1000 | SZ1500 | SZ2400 | ZD500 | |

| Axis(mm) | X | 700 | 1000 | 1000 | 1200 | 700 | |

| Y | 700 | 1000 | 1500 | 2400 | 5000 | ||

| Z | 100 | 100 | 100 | 100 | 100 | ||

| Dimension(mm) | L | 1050 | 1520 | 1765 | 1765 | 2015 | 6100 |

| W | 850 | 1150 | 1350 | 2050 | 2870 | 1180 | |

| H | 1500 | 1350 | 1350 | 1400 | 1350 | 1500 | |

| Weight(kg) | 255 | 350 | 400 | 450 | 600 | 1000 | |

| Package volum(CBM) | 1.2 | 3.5 | 4.5 | 5.5 | 9 | 12 | |

| Rated power consumption | 380/220/110V 50/60Hz 900W (Optional) | ...2000W | |||||

| Moving Speed | 300mm/s(Max 500mm/s not suggested) | ||||||

| Moving Precise | ±0.05mm | ||||||

| Moving Path | Point, line, square, circle, arc,dome | ||||||

| Glue mixing ratio | 1:1~10:1 | ||||||

| Potting Speed | 10-150g/5s(Adjustable) | ||||||

| Potting Precise | Amount±1%, Ratio:±1% | ||||||

| Air Pressure | 0.5-0.8MPa | ||||||

| Head Sealing pressure | MAX≤2.6Mpa | ||||||

| Glue water viscosity | <10000CPS(inquiry for above) | ||||||

| Operation Method | Auto, Manual | ||||||

| Program Method | Teaching Program | ||||||

| Electronic Control System | Smart control card+PLC+Touch Screen (Program setting, modify, save) | ||||||

| Glue Stop System | A, B Glue independent movement auto resorption system | ||||||

| Mixing Stirring System | High speed dynamic stirring mixing device(static option) | ||||||

| Glue ratio control | High precise metering pump | ||||||

| A,B glue supply system | A | High precise gear/screw pump 6-12CC | Bucket stirring optional | Heating optional | 20-50L Customizable | Vacuumable | |

| B | High precise pressure gear/screw pump 0.6-2.4CC | ||||||

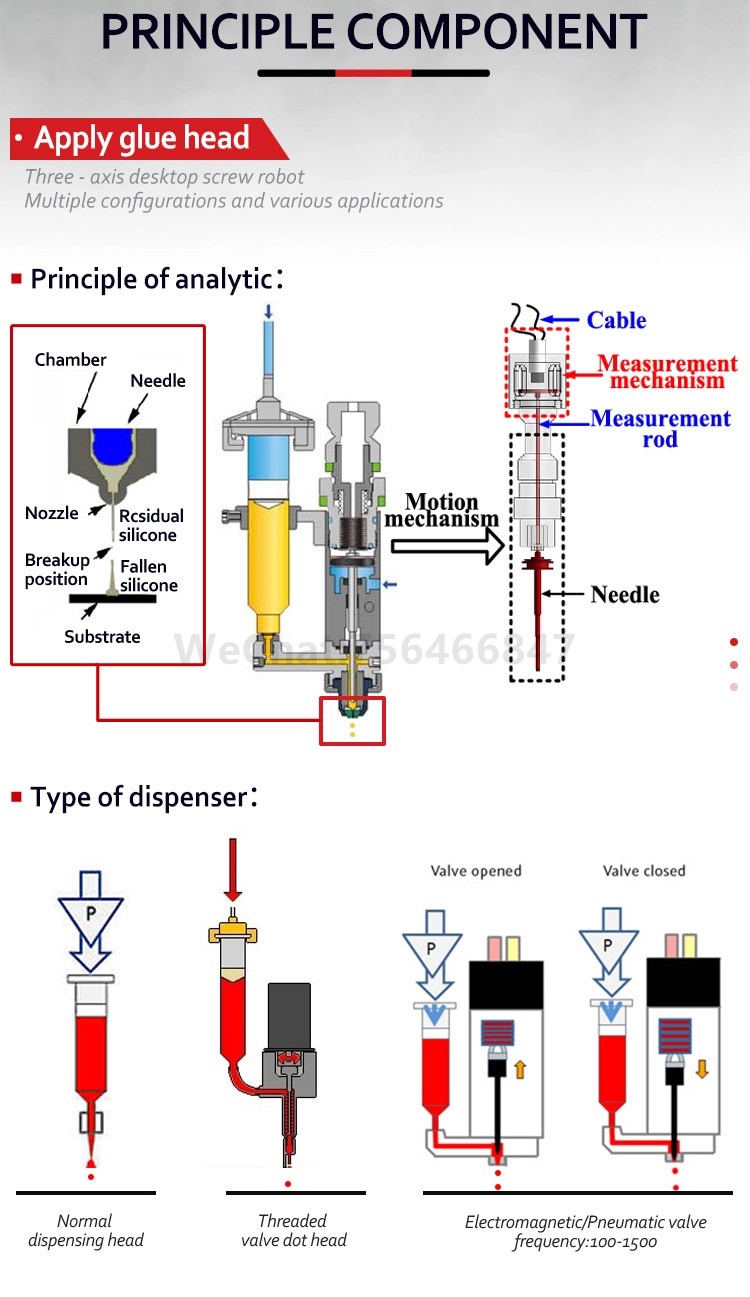

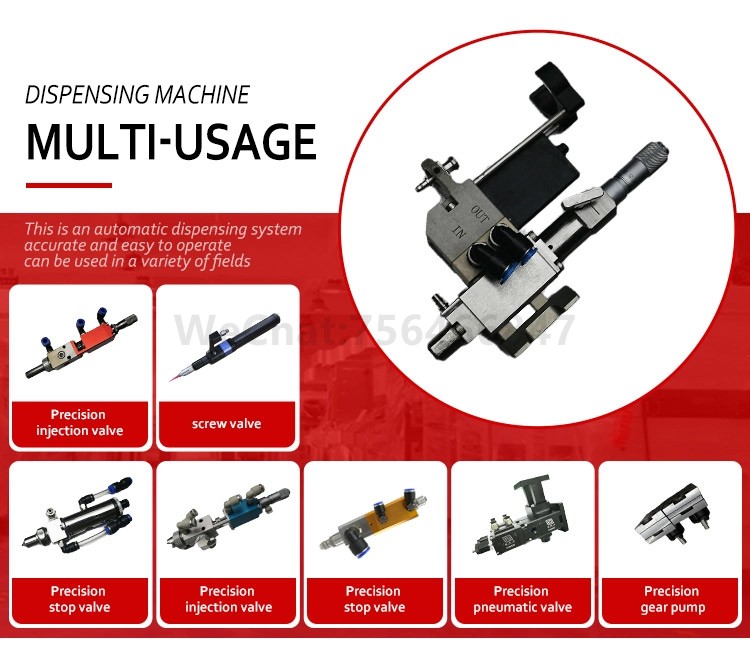

Glue machine

This glue dispensing&coating machine is suitable for high efficiency, high operation precision, high glue proportion production process; mainly used in: crafts, label signs, wall stickers, electronic products and other industries glue dispensing process.

Main features:

1.Two component A&B glue high pressure supply system and metering dispensing system with high precision and automatic identification and positioning functions;

2.High precision grinding grade wcrew rod,slider,rail,and Mitsubishi servo motor,Top grade materials,

3.Adopt professional industrial control PLC/PC computer system, original motor, electronic components, wiring, dustproof, anti-static system are designed according to national standards.

4.English interface provided and easy operate easy maintain.

There are variaty of configurations for different technique processing. Different glue and glue ratio, substrate,surface, program or dispensing type may effect on the configurations of the machine.

So provide glue TDS to us is important.

Features

Strong electric control system: using imported Panasonic PLC, the original motor, touch screen, electr onic components, wiring, dust-proof, anti-static system are designed according to the national standar ds.Glue Dispensing Accuracy: high precision gear pump, large glue amount and glue mixing ratio with new technological breakthroughs.A, B glue liquid level alarm function: Can avoid the glue supplying breaks

1 Q: Are you trading conpany or manufacturer?

A: We are manufacture.

2 Q: What is your terms of packing?

A: Generally, we pack our goods in hard brown box for small machine and plywood box for big machine.

3 Q: What is your terms of payment?

A: Payment≤10000 USD, 100% T/T in advance. Payment≥10000 USD, 50% T/T in advance, balance before shipment.

4 Q: What is your terms of delivery?

A: Sea shipping, air shipping

5 Q: How about your delivery time?

A: 7-25 days after receiving down payment. The specific time depends on the items and the quantity of your order.

6 Q: Can you produce according to the samples testing?

A: Yes, we can make testing by your sample or technical drawing.

7 Q: Do you test all your goods before delivery?

A: Yes, we test at least 5 times before shipping and running for 1 day or more.

8 Q: Warranty and after sales service

A: We provide 1 year warranty free for spare parts, Whole life technical support.

COMPANY:Shenzhen Jietongtai Technology Co., Ltd

Contact:Mr. Zhou

Tel:13410974163

Phone:15338087819

Email:mail@jietongtai.com

Add:A3 Floor, Hongda Phase III Factory, No. 9-2 Xingye 3rd Road, Fenghuang Community, Fuyong Street, Bao'an District, Shenzhen