two-component AB glue mixer machine pouring compound ratio 10:1/1:1/100:12 automatic glue filling machine

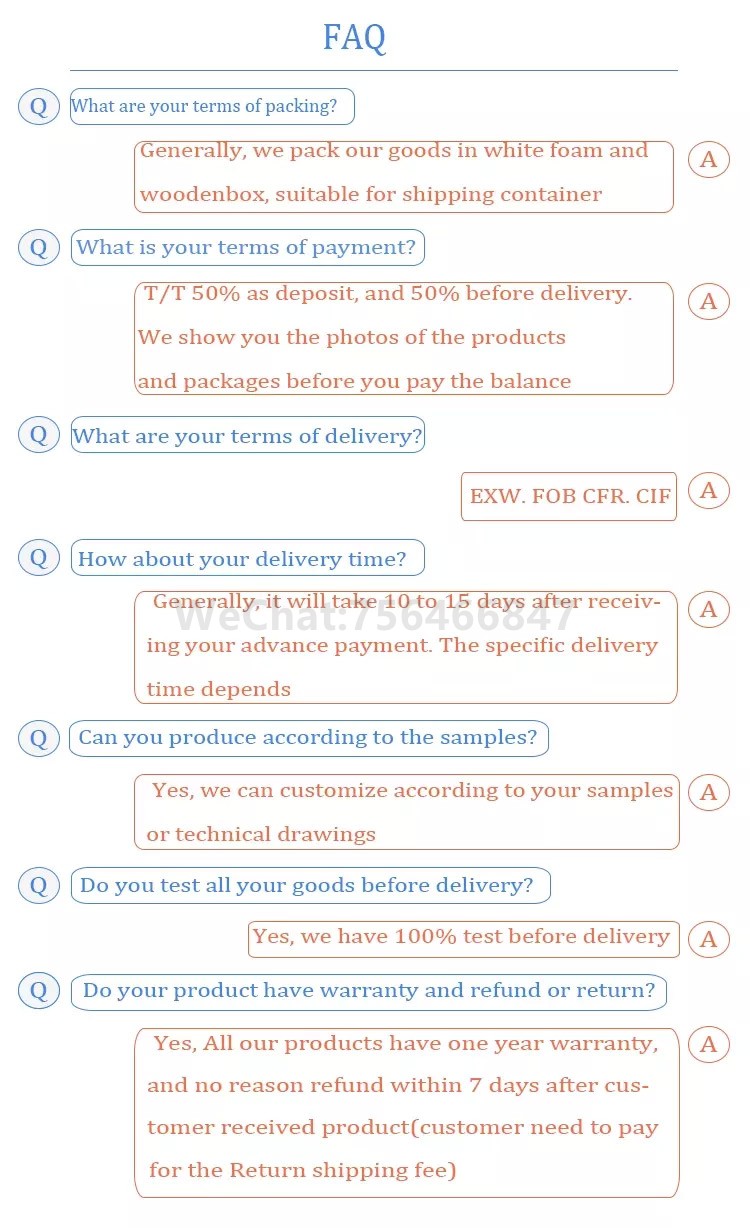

Packaging & Delivery

Selling Units:Single item

Single package size: 143X65X129cm

Single gross weight:252kg

Package Type:wooden box

Lead Time :

Quantity(Sets) 1 - 1 >1

Est. Time(days) 15 To be negotiated

Parameter | |

Control System: | Automatic glue filling system |

Glue flow: | 0.5-20g/s |

Matching accuracy: | ±3% |

Dispensing accuracy: | ±3% |

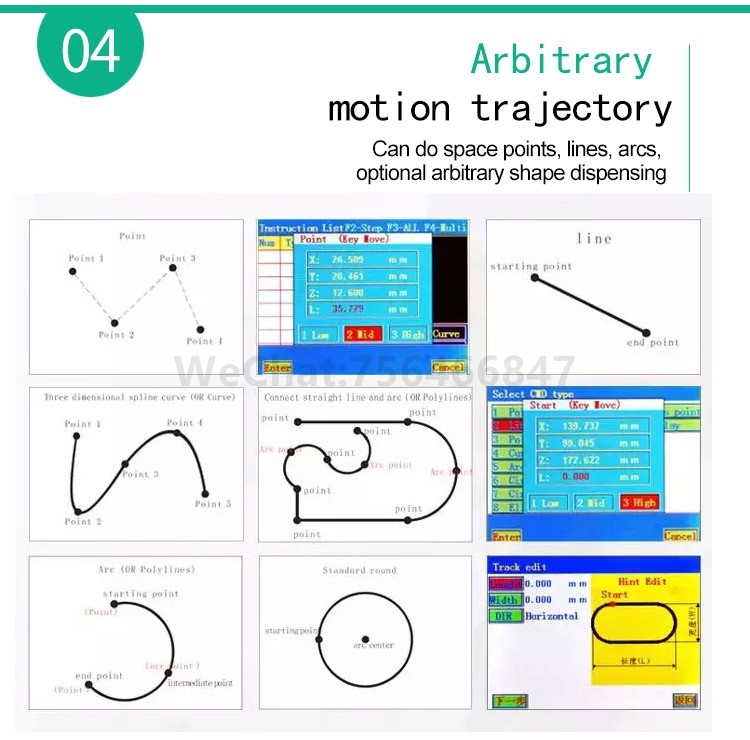

Operation method: | Dynamic glue out / static glue out |

Glue bucket heating: | A barrel / B barrel are heated separately |

Vacuum pump: | None (can be added) |

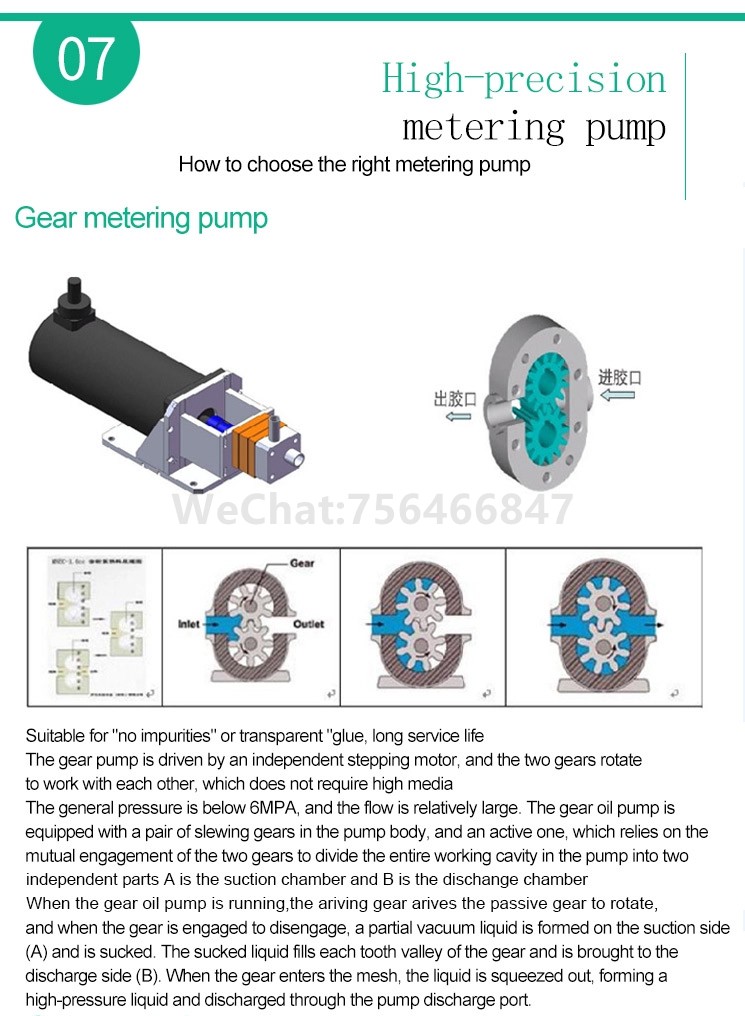

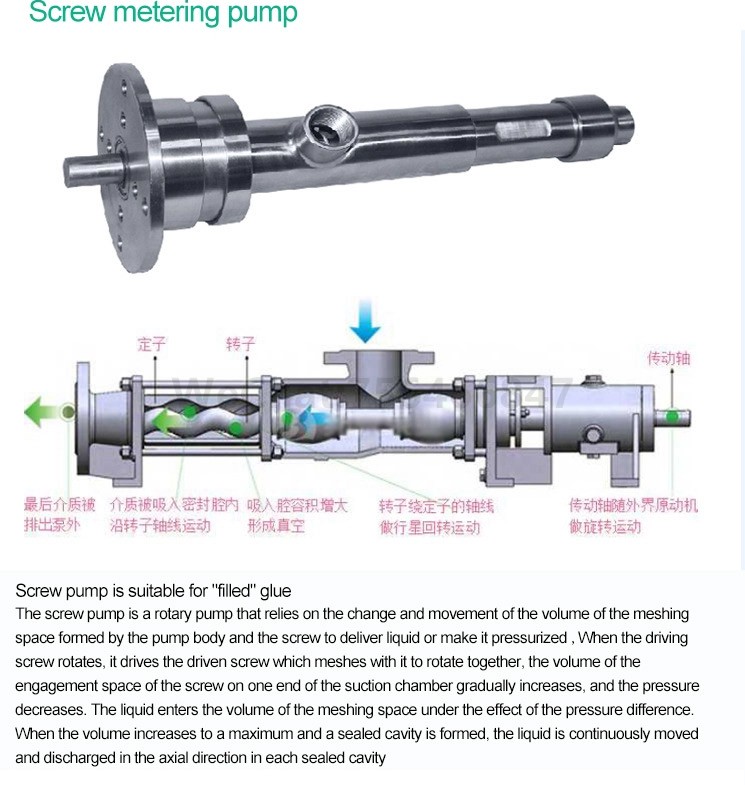

Measurement method: | Stepper motor + gear pump / screw pump (optional) |

Plastic bucket capacity: | A barrel 20L, B barrel 20L (optional) |

Cleaning the solvent tank: | 2L (optional) |

Working air source: | 0.5-0.6MPA |

Dispensing method: | Switchable timing / quantitative |

Mixing ratio: | 1:1-10:1(Optional) |

Glue : | Epoxy resin / polyurethane / silicone |

Measurement accuracy: | ±3% |

Display method: | touch screen |

Dispensing method: | Bucket A / B automatically stirs separately |

Glue bucket vacuum: | Reserved vacuum interface |

Alarm method: | Sound and light reminder of lack of material in glue bucket |

Feeding method: | Double metering pump |

Cleaning function: | exist |

Operating Voltage: | AC220V50-60HZ |

Machine power: | 0.8KW |

Anti-curing function: | Time can be set freely |

Features:

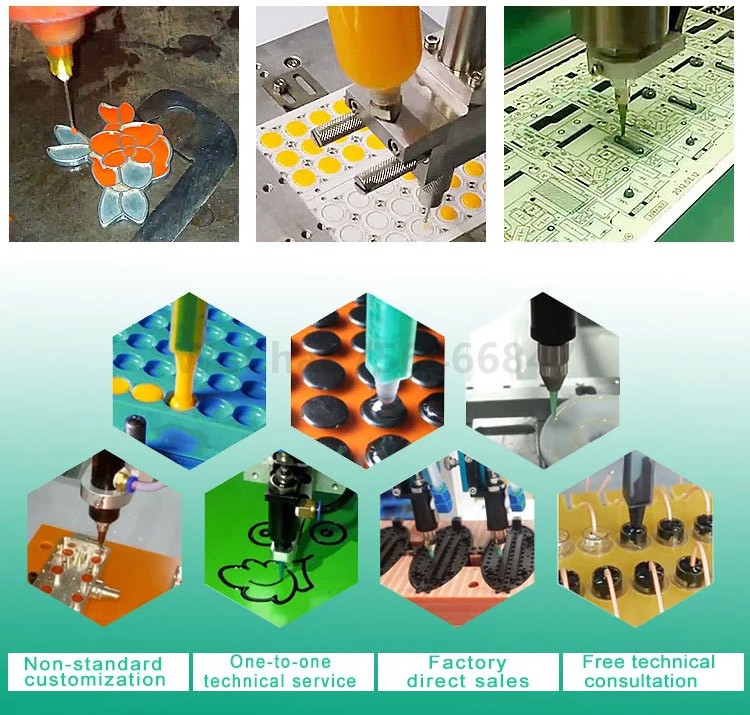

| The function of the AB glue filling machine is mainly to mix the AB two groups of glue in accordance with the set ratio and the amount of glue, and automatically mix evenly after the good proportion, and evenly pour into each product in the environment where the vacuum is pre-extracted to achieve A glue-free bubble-filling operation is generally aimed at products with higher requirements. |

1.Feature Description: | 1)According to the required ratio-precise mixing The two-component AB glue is precisely mixed in proportion. The ratio of glue needs to be mixed immediately to save glue waste. 2) Continuous feeding-AB glue is supplied independently 3) To achieve continuous automatic glue supply, equipped with two 50L stainless steel storage barrels, scheduled metering pumps, AB glue storage and storage independently, A barrel mixing and other functions. 4) Precise automatic quantitative glue filling, humanized operation interface, can set the number of glue filling, glue filling amount, glue filling time, etc The operation is simple and convenient. 5) Automatic glue filling-precise positioning The automatic glue filling system is loaded on the three-axis platform to realize automatic glue filling, saving manpower operation and higher glue filling efficiency. |

2. Applicable glue: | 1) The viscosity of the glue is within 50000cps. 2) Epoxy resin, polyurethane, electronic silicone, electronic potting glue, liquid silicone and other two-component glue. 3) The size of the filled particles is greater than 200 microns, and the proportion is less than 50% of the total amount of glue. 4) Adjustable range of mixing ratio 1: 1, 1: 2, 1: 3, 1: 4, 1: 5, 1:10. |

3. Supply capacity: | 1) Measurement and matching accuracy: ± 1%. 2) Accuracy of glue output: ± 2%. 3) Dispensing speed: minimum 1 gram per second, maximum 10 gram per second (the amount of glue can be changed according to the viscosity of the glue). |

COMPANY:Shenzhen Jietongtai Technology Co., Ltd

Contact:Mr. Zhou

Tel:13410974163

Phone:15338087819

Email:mail@jietongtai.com

Add:A3 Floor, Hongda Phase III Factory, No. 9-2 Xingye 3rd Road, Fenghuang Community, Fuyong Street, Bao'an District, Shenzhen